RET Teachers: Andy Durkcas, Kristian Messina and Jaime Hainer Advisor: Professor Chris Kobus RET teachers Andy Durkacs(Oak Park Schools-Math Teacher), Kristina Messina (Oak Park Schools-Math Teacher), and Jaime Hainer (Grosse Pointe Schools -Science Teacher) are working with Dr. Kobus to test the thermal conductivity and structural integrity of various samples of concrete. Specifically, we are mixing different amounts of extruded polystyrene foam with the aggregate of the concrete. As more polystyrene is added, the concrete becomes a better insulator. The tradeoff to this is that the structural integrity of the concrete becomes weaker.

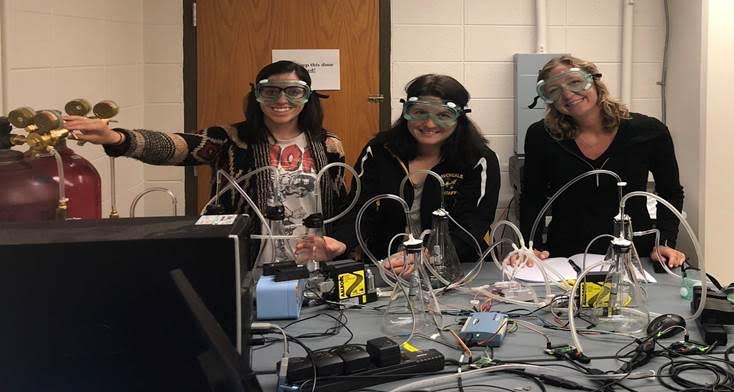

RET Teachers: Amy Brown, Lauren McCulloch and Jennifer Diemert Advisor: Professor Jonathan Maissonneuve RET teachers Amy Brown (Avondale Schools), Lauren McCulloch (Grosse Pointe Schools), and Jennifer Diemert (Rochester Community Schools) spent the summer working on two projects that use the same experimental bench. Both of these projects are led by Dr. Jonathan Maissonneuve and his team of graduate students, Gucheng Yuan and Gayatri Lekshminarayanan. The research involves mixing humid and dry air across a membrane. Gucheng's project (Using Humidity Gradients to Generate Power) investigates generating power when water passes through the membrane from the wet to the dry side and has real world applications of using flue gas mixing with humid outside air across a membrane. Gayatri's project (Desiccant/Membrane Dehumidification Process for Energy Efficient Air Conditioning) is driven by DTE's E-Challenge in hopes to replace traditional dehumidification methods in an HVAC system with a membrane to save electrical energy. RET Teachers: George Bazzell and Stephen Kim Advisors: Professor Dan Delvescovo and Professor Dave Schall RET Teacher George Bazzell (Oak Park Schools-Math Teacher) and Stephen Kim (Grosse Pointe Schools-Chemistry Teacher), are researching the effects of fuel dilution on engine oil in turbo and supercharged combustion engines. We are analyzing oil and fuel samples using the FTIR Spectrometer as well as samples of fuel-diluted oil to compare the impurities within the oil samples at different dilution percentages. This data will be used as a baseline to compare the engine oil that is being cycled through an apparatus that models routine engine oil use in a car. Oil will run through a typical temperature cycle to closely resemble how it behaves in car engines, and it will be diluted with fuel in the process. After hundreds of cycles, the oil will be analyzed and compared with the baseline data that was collected. RET Teachers: Delisa Ervin-Barnard, Stacey D. Jackson and Jennifer Gwilt Advisor: Professor Brian Dean Inertial Measurement Units (IMU's) have become increasingly popular for Human Motion tracking and analysis. They can be used for a variety of tasks spanning from virtual reality gaming to physical rehabilitation. The human motion project was tasked with reducing the number of sensors it takes to track the human body. The initial research used two IMUs to track the flexion of the knee. To reduce the cost and amount of sensors used without losing precision, the sensors were reduced to one flex sensor placed on the knee to capture the flexion through changes in electrical resistance. The RET participants were tasked with making the technology wearable and work to increase the precision of the data. The flex sensor was mounted in a pair of leggings, and the sensor's change in resistance was measured and analyzed using a Wheatstone Bridge circuit and an Arduino streaming data to MATLAB

RET Teachers: Kate Hojnacki, Heather Vingsness and Eric Thuma Advisor: Professor Lianxing Yang Vacuum cups are used in automotive stamping processes to move lubricated aluminium sheets along the stamping line. Failure of a vacuum cup can cause dropped or slipping parts, which can cause expensive delays for the stamping plant. In this experiment, we used a tensile tester to separate a vacuum cup from an aluminium surface while simultaneously recording the process using two calibrated cameras. Digital image correlation software provided opportunities for analysis of deformation and strain in the vacuum cup. |

Funded by the National Science Foundation through Award #1542333